Advancing the state of the art in the field of ADCS, a novel type of attitude control actuator known as Fluid Dynamic Actuator (FDA) has been developed at TU Berlin]. The principle of operation of these actuators is the same as reaction wheels, namely exchange of angular momentum.

Advancing the state of the art in the field of ADCS, a novel type of attitude control actuator known as Fluid Dynamic Actuator (FDA) has been developed at TU Berlin]. The principle of operation of these actuators is the same as reaction wheels, namely exchange of angular momentum.

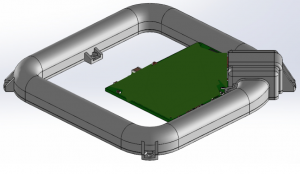

FDAs consist of a closed channel that is filled with a liquid metal and a driver unit composed of a controller printed circuit board (PCB) and an electromagnetic pump that accelerates the fluid within the channel, thereby creating an angular momentum which results in the overall system moving in the opposite direction due to conservation of angular momentum.

Project advisor Dr. Sebastian Grau introduced a miniaturized version of FDAs, known as pFDAs, in “Contributions to the Advance of Integration Density of CubeSats”. A key advantage of this type of actuator, besides its reduction in size when compared with FDAs, is that the fluid channel can be shaped in a variety of ways depending on the mission requirements; for example, an L-shaped channel affords redundancy by producing an angular momentum vector that is not constrained to a single plane in the body-fixed frame of the satellite, while planar pFDAs allow satellite designers to optimize for volume efficiency.

L-shaped pFDAs were planned to be tested on the TUPEX-6 mission to confirm the efficacy of the generated redundant angular momentum vectors in attitude control. The BEESAT-9 mission plans to perform in-orbit tests of a number of attitude control modes using a single pFDA in combination with reaction wheels and magnetic coils.

TUPEX-7 will test planar actuators to verify not only that three-axis attitude control is possible, but that through integration of the planar pFDAs onto the side panels of the experiment an increase volumetric efficiency is inherently demonstrated.